Modbus Controller¶

The modbus_controller component creates a RS485 connection to either:

control a Modbus server (slave) device, letting your ESPHome node to act as a Modbus client (master). You can access the coils, inputs, holding, read registers from your devices as sensors, switches, selects, numbers or various other ESPHome components and present them to your favorite Home Automation system. You can even write them as binary or float ouptputs from ESPHome.

let your ESPHome node act as a Modbus server, allowing a ModBUS client to read data (like sensor values) from your ESPHome node.

To choose the role, set the role attribute of the Modbus Component upon which this modbus_controller component relies. client is the default.

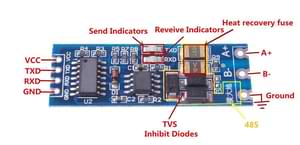

Hardware setup¶

You need an RS485 transceiver module:

See How is this RS485 module working? on stackexchange for more details.

The transceiver connects to the UART of the MCU. For ESP32, pin 16 to TXD and pin 17 to RXD are the default ones but any other pins can be used as well. 3.3V to VCC and naturally GND to GND.

On the bus side, you need 120 Ohm termination resistors at the ends of the bus cable as per Modbus standard. Some transceivers have this already soldered onboard, while some slave devices may have them available via a jumper or a DIP switch.

Note

If you are using an ESP8266, serial logging may cause problems reading from UART. For best results, hardware serial is recommended. Software serial may not be able to read all received data if other components spend a lot of time in the loop().

For hardware serial only a limited set of pins can be used. Either tx_pin: GPIO1 and rx_pin: GPIO3 or tx_pin: GPIO15 and rx_pin: GPIO13.

The disadvantage of using the hardware UART is that you can’t use serial logging because the serial logs would be sent to the Modbus device(s) instead, causing errors.

Serial logging can be disabled by setting baud_rate: 0.

See Logger Component for more details

logger:

level: <level>

baud_rate: 0

Configuration variables:¶

modbus_id (Optional, ID): Manually specify the ID of the

modbushub.address (Required, ID): The Modbus address of the slave device.

allow_duplicate_commands (Optional, boolean): Whether to allow duplicate commands in the queue. Defaults to

false.command_throttle (Optional, Time): minimum time in between 2 requests to the device. Default is

0ms. Some Modbus slave devices limit the rate of requests from the master, so this allows the interval between requests to be altered.update_interval (Optional, Time): The interval that the sensors should be checked. Defaults to 60 seconds.

offline_skip_updates (Optional, integer): When a slave doesn’t respond to a command, it is marked as offline, you can specify how many updates will be skipped while it is offline. If using a bus with multiple slaves, this avoids waiting for timeouts allowing to read other slaves in the same bus. When the slave responds to a command, it’ll be marked online again.

max_cmd_retries (Optional, integer): How many times a command will be retried if no response is received. It doesn’t include the initial transmition. Defaults to 4.

server_registers (Optional): A list of registers that are responded to when acting as a server. - address (Required, integer): start address of the first register in a range - value_type (Optional): datatype of the mod_bus register data. The default data type for ModBUS is a 16 bit integer in big endian format (MSB first)

U_WORD: unsigned 16 bit integer from 1 register = 16bitS_WORD: signed 16 bit integer from 1 register = 16bitU_DWORD: unsigned 32 bit integer from 2 registers = 32bitS_DWORD: signed 32 bit integer from 2 registers = 32bitU_DWORD_R: unsigned 32 bit integer from 2 registers low word firstS_DWORD_R: signed 32 bit integer from 2 registers low word firstU_QWORD: unsigned 64 bit integer from 4 registers = 64bitS_QWORD: signed 64 bit integer from 4 registers = 64bitU_QWORD_R: unsigned 64 bit integer from 4 registers low word firstS_QWORD_R: signed 64 bit integer from 4 registers low word firstFP32: 32 bit IEEE 754 floating point from 2 registersFP32_R: 32 bit IEEE 754 floating point - same as FP32 but low word first

Defaults to

U_WORD.read_lambda (Required, lambda): Lambda that returns the value of this register.

Automations:

on_command_sent (Optional, Automation): An automation to perform when a modbus command has been sent. See on_command_sent

on_online (Optional, Automation): An automation to perform when a modbus controller goes online. See on_online

on_offline (Optional, Automation): An automation to perform when a modbus controller goes offline. See on_offline

Example Client¶

The following code creates a modbus_controller hub talking to a ModBUS device at address 1 with 115200 bps

ModBUS sensors can be directly defined (inline) under the modbus_controller hub or as standalone components

Technically there is no difference between the “inline” and the standard definitions approach.

# Example configuration entry

uart:

...

modbus:

flow_control_pin: GPIOXX

id: modbus1

modbus_controller:

- id: modbus_device

address: 0x1 ## address of the Modbus slave device on the bus

modbus_id: modbus1

setup_priority: -10

sensor:

- platform: modbus_controller

modbus_controller_id: modbus_device

name: "Battery Capacity"

register_type: holding

address: 0x9001 ## address of the register inside the Modbus slave device

unit_of_measurement: "AH"

value_type: U_WORD

switch:

- platform: modbus_controller

modbus_controller_id: modbus_device

name: "Reset to Factory Default"

register_type: coil

address: 0x15

bitmask: 1

text_sensor:

- name: "rtc_clock"

platform: modbus_controller

modbus_controller_id: modbus_device

id: rtc_clock

internal: true

register_type: holding

address: 0x9013

register_count: 3

raw_encode: HEXBYTES

response_size: 6

The configuration example above creates a modbus_controller hub talking to a Modbus device at address 1 with a baudrate of 115200 bps, implementing a sensor, a switch and a text sensor.

Example Server¶

The following code allows a ModBUS client to read a sensor value from your ESPHome node, that the node itself read from a ModBUS server.

uart:

- id: uart_modbus_client

tx_pin: 32

rx_pin: 34

- id: uart_modbus_server

tx_pin: 25

rx_pin: 35

modbus:

- uart_id: uart_modbus_client

id: modbus_client

- uart_id: uart_modbus_server

id: modbus_server

role: server

modbus_controller:

- id: modbus_evse

modbus_id: modbus_client

address: 0x2

update_interval: 5s

- modbus_id: modbus_server

address: 0x4

server_registers:

- address: 0x0002

value_type: S_DWORD_R

read_lambda: |-

return id(evse_voltage_l1).state;

sensor:

- platform: modbus_controller

id: evse_voltage_l1

modbus_controller_id: modbus_evse

name: "EVSE voltage L1"

register_type: holding

address: 0x0000

device_class: voltage

value_type: S_DWORD_R

accuracy_decimals: 1

unit_of_measurement: V

filters:

- multiply: 0.1

Check out the various Modbus components available at the bottom of the document in the Automation section. They can be directly defined (inline) under the modbus_controller hub or as standalone components. Technically there is no difference between the inline and the standard definitions approach.

Below you find a few general tips about using Modbus in more advanced scenarios. Applicable component functionalities have links pointing here:

Bitmasks¶

Some devices use decimal values in read registers to show multiple binary states occupying only one register address. To decode them, you can use bitmasks according to the table below. The decimal value corresponding to a bit is always double of the previous one in the row. Multiple bits can be represented in a single register by making a sum of all the values corresponding to the bits.

Alarm bit |

Description |

DEC value |

HEX value |

|---|---|---|---|

bit 0 |

Binary Sensor 0 |

1 |

1 |

bit 1 |

Binary Sensor 1 |

2 |

2 |

bit 2 |

Binary Sensor 2 |

4 |

4 |

bit 3 |

Binary Sensor 3 |

8 |

8 |

bit 4 |

Binary Sensor 4 |

16 |

10 |

bit 5 |

Binary Sensor 5 |

32 |

20 |

bit 6 |

Binary Sensor 6 |

64 |

40 |

bit 7 |

Binary Sensor 7 |

128 |

80 |

bit 8 |

Binary Sensor 8 |

256 |

100 |

bit 9 |

Binary Sensor 9 |

512 |

200 |

bit 10 |

Binary Sensor 10 |

1024 |

400 |

bit 11 |

Binary Sensor 11 |

2048 |

800 |

bit 12 |

Binary Sensor 12 |

4096 |

1000 |

bit 13 |

Binary Sensor 13 |

8192 |

2000 |

bit 14 |

Binary Sensor 14 |

16384 |

4000 |

bit 15 |

Binary Sensor 15 |

32768 |

8000 |

In the example below, register 15, holds several binary values. It stores the decimal value 12288, which is the sum of 4096 + 8192, meaning the corresponding bits 12 and 13 are 1, the other bits are 0.

To gather some of these bits as binary sensors in ESPHome, use bitmask:

binary_sensor:

- platform: modbus_controller

modbus_controller_id: modbus1

name: Alarm bit0

register_type: read

address: 15

bitmask: 0x1

- platform: modbus_controller

modbus_controller_id: modbus1

name: Alarm bit1

register_type: read

address: 15

bitmask: 0x2

- platform: modbus_controller

modbus_controller_id: modbus1

name: Alarm bit10

register_type: read

address: 15

bitmask: 0x400

- platform: modbus_controller

modbus_controller_id: modbus1

name: Alarm bit15

register_type: read

address: 15

bitmask: 0x8000

Using custom_command¶

custom_command can be used to create an arbitrary modbus command. Combined with a lambda any response can be handled.

This example re-implements the command to read the registers 0x156 (Total active energy) and 0x158 Total (reactive energy) from a SDM-120.

SDM-120 returns the values as floats using 32 bits in 2 registers.

uart:

id: mod_uart

...

modbus:

send_wait_time: 200ms

uart_id: mod_uart

id: mod_bus

modbus_controller:

- id: sdm

address: 2

modbus_id: mod_bus

command_throttle: 100ms

setup_priority: -10

update_interval: 30s

sensors:

- platform: modbus_controller

modbus_controller_id: sdm

name: "Total active energy"

id: total_energy

# address: 0x156

# register_type: "read"

## reimplement using custom_command

# 0x2 : modbus device address

# 0x4 : modbus function code

# 0x1 : high byte of modbus register address

# 0x56: low byte of modbus register address

# 0x00: high byte of total number of registers requested

# 0x02: low byte of total number of registers requested

custom_command: [ 0x2, 0x4, 0x1, 0x56,0x00, 0x02]

value_type: FP32

unit_of_measurement: kWh

accuracy_decimals: 1

- platform: modbus_controller

modbus_controller_id: sdm

name: "Total reactive energy"

# address: 0x158

# register_type: "read"

custom_command: [0x2, 0x4, 0x1, 0x58, 0x00, 0x02]

## the command returns an float value using 4 bytes

lambda: |-

ESP_LOGD("Modbus Sensor Lambda","Got new data" );

union {

float float_value;

uint32_t raw;

} raw_to_float;

if (data.size() < 4 ) {

ESP_LOGE("Modbus Sensor Lambda", "invalid data size %d",data.size());

return NAN;

}

raw_to_float.raw = data[0] << 24 | data[1] << 16 | data[2] << 8 | data[3];

ESP_LOGD("Modbus Sensor Lambda", "FP32 = 0x%08X => %f", raw_to_float.raw, raw_to_float.float_value);

return raw_to_float.float_value;

unit_of_measurement: kVArh

accuracy_decimals: 1

Optimizing modbus communications¶

register_count is an option only required for uncommon response encodings or to optimizie modbus communications.

It describes the number of registers this data point spans, overriding the defaults determined by value_type. If no value for register_count is provided, it is calculated based on the register type. The default size for one register is 16 bits (one word). Some devices are not adhering to this convention and have registers larger than 16 bits. In this case, register_count and response_size must be set. For example, if your Modbus device uses one register for a FP32 value (instead of the default of two), set register_count: 1 and response_size: 4.

register_count can also be used to skip a number of registers in consecutive range.

An example is an SDM meter, with interesting data in register addresses 0, 2, 4 and 6:

- platform: modbus_controller

name: "Voltage Phase 1"

address: 0

register_type: "read"

value_type: FP32

- platform: modbus_controller

name: "Voltage Phase 2"

address: 2

register_type: "read"

value_type: FP32

- platform: modbus_controller

name: "Voltage Phase 3"

address: 4

register_type: "read"

value_type: FP32

- platform: modbus_controller

name: "Current Phase 1"

address: 6

register_type: "read"

value_type: FP32

accuracy_decimals: 1

The configuration above will generate one modbus command read multiple registers from 0 to 6.

Maybe you don’t care about the data in register addresses 2 and 4, which are voltage values for Phase 2 and Phase 3 (or you have a SDM-120).

Of course, you can delete the sensors your don’t care about, but then you’d have a gap in the addresses. If you remove the registers at address 2 and 4, two commands will be generated – read register 0 and read register 6. To avoid generating multiple commands and thus reduce activity on the bus, register_count can be used to fill the gaps:

- platform: modbus_controller

name: "Voltage Phase 1"

address: 0

unit_of_measurement: "V"

register_type: "read"

value_type: FP32

register_count: 6

- platform: modbus_controller

name: "Current Phase 1"

address: 6

register_type: "read"

value_type: FP32

Because the option register_count: 6 is used for the first sensor, one command read multiple registers from 0 to 6 will be used but the values in between will be ignored.

Note

Calculation: FP32 is a 32 bit value and uses 2 registers. Therefore, to skip the 2 FP32 registers the size of these 2 registers must be added to the default size for the first register. So we have 2 for address 0, 2 for address 2 and 2 for address 4 thus register_count must be 6.

Protocol decoding example¶

sensors:

- platform: modbus_controller

modbus_controller_id: epever

id: array_rated_voltage

name: "array_rated_voltage"

address: 0x3000

unit_of_measurement: "V"

register_type: read

value_type: U_WORD

accuracy_decimals: 1

skip_updates: 60

filters:

- multiply: 0.01

- platform: modbus_controller

modbus_controller_id: epever

id: array_rated_current

name: "array_rated_current"

address: 0x3001

unit_of_measurement: "V"

register_type: read

value_type: U_WORD

accuracy_decimals: 2

filters:

- multiply: 0.01

- platform: modbus_controller

modbus_controller_id: epever

id: array_rated_power

name: "array_rated_power"

address: 0x3002

unit_of_measurement: "W"

register_type: read

value_type: U_DWORD_R

accuracy_decimals: 1

filters:

- multiply: 0.01

- platform: modbus_controller

modbus_controller_id: epever

id: battery_rated_voltage

name: "battery_rated_voltage"

address: 0x3004

unit_of_measurement: "V"

register_type: read

value_type: U_WORD

accuracy_decimals: 1

filters:

- multiply: 0.01

- platform: modbus_controller

modbus_controller_id: epever

id: battery_rated_current

name: "battery_rated_current"

address: 0x3005

unit_of_measurement: "A"

register_type: read

value_type: U_WORD

accuracy_decimals: 1

filters:

- multiply: 0.01

- platform: modbus_controller

modbus_controller_id: epever

id: battery_rated_power

name: "battery_rated_power"

address: 0x3006

unit_of_measurement: "W"

register_type: read

value_type: U_DWORD_R

accuracy_decimals: 1

filters:

- multiply: 0.01

- platform: modbus_controller

modbus_controller_id: epever id: charging_mode

name: "charging_mode"

address: 0x3008

unit_of_measurement: ""

register_type: read

value_type: U_WORD

accuracy_decimals: 0

To minimize the required transactions all registers with the same base address are read in one request.

The response is mapped to the sensor based on register_count and offset in bytes. For example:

Request

data |

description |

|---|---|

0x1 (01) |

device address |

0x4 (04) |

function code 4 (Read Input Registers) |

0x30 (48) |

start address high byte |

0x0 (00) |

start address low byte |

0x0 (00) |

number of registers to read high byte |

0x9 (09) |

number of registers to read low byte |

0x3f (63) |

crc |

0xc (12) |

crc |

Response

offset |

data |

value (type) |

description |

|---|---|---|---|

H |

0x1 (01) |

device address |

|

H |

0x4 (04) |

function code |

|

H |

0x12 (18) |

byte count |

|

0 |

0x27 (39) |

U_WORD |

array_rated_voltage high byte |

1 |

0x10 (16) |

0x2710 (100000) |

array_rated_voltage low byte |

2 |

0x7 (7) |

U_WORD |

array_rated_current high byte |

3 |

0xd0 (208) |

0x7d0 (2000) |

array_rated_current low byte |

4 |

0xcb (203) |

U_DWORD_R |

array_rated_power high byte of low word |

5 |

0x20 (32) |

spans 2 register |

array_rated_power low byte of low word |

6 |

0x0 (0) |

array_rated_power high byte of high word |

|

7 |

0x0 (0) |

0x0000CB20 (52000) |

array_rated_power low byte of high word |

8 |

0x9 (09) |

U_WORD |

battery_rated_voltage high byte |

9 |

0x60 (96) |

0x960 (2400) |

battery_rated_voltage low byte |

10 |

0x7 (07) |

U_WORD |

battery_rated_current high word |

11 |

0xd0 (208) |

0x7d0 (2000) |

battery_rated_current high word |

12 |

0xcb (203) |

U_DWORD_R |

battery_rated_power high byte of low word |

13 |

0x20 (32) |

spans 2 register |

battery_rated_power low byte of low word |

14 |

0x0 (0) |

battery_rated_power high byte of high word |

|

15 |

0x0 (0) |

0x0000CB20 (52000) |

battery_rated_power low byte of high word |

16 |

0x0 (0) |

U_WORD |

charging_mode high byte |

17 |

0x2 (02) |

0x2 (MPPT) |

charging_mode low byte |

C |

0x2f (47) |

crc |

|

C |

0x31 (49) |

crc |

Note

Write support is only implemented for switches and selects; however, the C++ code provides the required API to write to a Modbus device.

These methods can be called from a lambda.

Here is an example how to set config values to for an EPEVER Trace AN controller. The code synchronizes the localtime of MCU to the epever controller The time is set by writing 12 bytes to register 0x9013. Then battery charge settings are sent.

esphome:

on_boot:

## configure controller settings at setup

## make sure priority is lower than setup_priority of modbus_controller

priority: -100

then:

- lambda: |-

// get local time and sync to controller

time_t now = ::time(nullptr);

struct tm *time_info = ::localtime(&now);

int seconds = time_info->tm_sec;

int minutes = time_info->tm_min;

int hour = time_info->tm_hour;

int day = time_info->tm_mday;

int month = time_info->tm_mon + 1;

int year = time_info->tm_year % 100;

esphome::modbus_controller::ModbusController *controller = id(epever);

// if there is no internet connection localtime returns year 70

if (year != 70) {

// create the payload

std::vector<uint16_t> rtc_data = {uint16_t((minutes << 8) | seconds), uint16_t((day << 8) | hour),

uint16_t((year << 8) | month)};

// Create a Modbus command item with the time information as the payload

esphome::modbus_controller::ModbusCommandItem set_rtc_command =

esphome::modbus_controller::ModbusCommandItem::create_write_multiple_command(controller, 0x9013, 3, rtc_data);

// Submit the command to the send queue

epever->queue_command(set_rtc_command);

ESP_LOGI("ModbusLambda", "EPSOLAR RTC set to %02d:%02d:%02d %02d.%02d.%04d", hour, minutes, seconds, day, month,

year + 2000);

}

// Battery settings

// Note: these values are examples only and apply my AGM Battery

std::vector<uint16_t> battery_settings1 = {

0, // 9000 Battery Type 0 = User

0x0073, // 9001 Battery Cap 0x55 == 115AH

0x012C, // 9002 Temp compensation -3V /°C/2V

0x05DC, // 9003 0x5DC == 1500 Over Voltage Disconnect Voltage 15,0

0x058C, // 9004 0x58C == 1480 Charging Limit Voltage 14,8

0x058C, // 9005 Over Voltage Reconnect Voltage 14,8

0x05BF, // 9006 Equalize Charging Voltage 14,6

0x05BE, // 9007 Boost Charging Voltage 14,7

0x0550, // 9008 Float Charging Voltage 13,6

0x0528, // 9009 Boost Reconnect Charging Voltage 13,2

0x04C4, // 900A Low Voltage Reconnect Voltage 12,2

0x04B0, // 900B Under Voltage Warning Reconnect Voltage 12,0

0x04BA, // 900c Under Volt. Warning Volt 12,1

0x04BA, // 900d Low Volt. Disconnect Volt. 11.8

0x04BA // 900E Discharging Limit Voltage 11.8

};

// Boost and equalization periods

std::vector<uint16_t> battery_settings2 = {

0x0000, // 906B Equalize Duration (min.) 0

0x0075 // 906C Boost Duration (aka absorb) 117 mins

};

esphome::modbus_controller::ModbusCommandItem set_battery1_command =

esphome::modbus_controller::ModbusCommandItem::create_write_multiple_command(controller, 0x9000, battery_settings1.size() ,

battery_settings1);

esphome::modbus_controller::ModbusCommandItem set_battery2_command =

esphome::modbus_controller::ModbusCommandItem::create_write_multiple_command(controller, 0x906B, battery_settings3.size(),

battery_settings2);

delay(200) ;

controller->queue_command(set_battery1_command);

delay(200) ;

controller->queue_command(set_battery2_command);

ESP_LOGI("ModbusLambda", "EPSOLAR Battery set");

uart:

id: mod_bus

tx_pin: GPIOXX

rx_pin: GPIOXX

baud_rate: 115200

stop_bits: 1

modbus:

#flow_control_pin: GPIOXX

send_wait_time: 200ms

id: mod_bus_epever

modbus_controller:

- id: epever

## the Modbus device addr

address: 0x1

modbus_id: mod_bus_epever

command_throttle: 0ms

setup_priority: -10

update_interval: ${updates}

sensor:

- platform: modbus_controller

modbus_controller_id: epever

id: array_rated_voltage

name: "array_rated_voltage"

address: 0x3000

unit_of_measurement: "V"

register_type: read

value_type: U_WORD

accuracy_decimals: 1

filters:

- multiply: 0.01

- platform: modbus_controller

modbus_controller_id: epever

id: array_rated_current

name: "array_rated_current"

address: 0x3001

unit_of_measurement: "A"

register_type: read

value_type: U_WORD

accuracy_decimals: 2

filters:

- multiply: 0.01

- platform: modbus_controller

modbus_controller_id: epever

id: array_rated_power

name: "array_rated_power"

address: 0x3002

unit_of_measurement: "W"

register_type: read

value_type: U_DWORD_R

accuracy_decimals: 1

filters:

- multiply: 0.01

Automation¶

on_command_sent¶

This automation will be triggered when a command has been sent by the modbus_controller. In Lambdas

you can get the function code in function_code and the register address in address.

modbus_controller:

- id: modbus_con

# ...

on_command_sent:

then:

- number.increment: modbus_commands

on_online¶

This automation will be triggered when a modbus_controller goes online, after been offline. In Lambdas

you can get the function code in function_code and the register address in address.

modbus_controller:

- id: modbus_con

# ...

on_online:

then:

- logger.log: "Controller back online!"

on_offline¶

This automation will be triggered when a modbus_controller goes offline (See offline_skip_updates). In Lambdas

you can get the function code in function_code and the register address in address.

modbus_controller:

- id: modbus_con

# ...

on_offline:

then:

- logger.log: "Controller goes offline!"